Making our products more sustainable is a fundamental goal for Leonardo Helicopters. As a responsible business, we are committed to reducing our environmental impact as part of our wider sustainability roadmap.

The Life Cycle Assessment project starts with a simple principle – you can only change what you can measure.

LCA will give us a structured method to assess the environmental impact of our products throughout their life, from the earliest stage of production all the way through to operations and disposal. Ultimately, it will help to create a more sustainable future for our vertical lift platforms.

Why are we doing it? Because protecting the environment matters to us and we know it matters to our customers and operators too. We face the same challenges: to decarbonise our operations. To find better ways to reduce the impact we have on the world around us. LCA provides the opportunity to work on these challenges together.

Helping to cut carbon

Within Leonardo Helicopters and across the wider Leonardo Group, we have set challenging targets in many different areas of environmental performance – reducing our carbon emissions, cutting water use, and reducing energy consumption to name just three. Our sustainability commitments are aligned with the Science-Based Targets initiative (SBTi) which is helping companies to play their part in combating the climate crisis.

But LCA is not only about compliance with those targets. Instead, it will create a roadmap for the future, helping us to reduce the environmental footprint of our products in a way that can be scaled up right across our product line.

AW139 leads the way

We started the project early in 2024, and in doing so became the first Leonardo business to launch LCA on a such large scale. We have conducted smaller-scale investigations at component level before, but this is a first at platform level.

We are starting with the AW139 – our best-selling commercial helicopter, with more than 1,000 of the type in service around the world. There are roughly 10,000 individual parts that go into the manufacture of an AW139, so it is a significant task to understand every element of the helicopter’s lifecycle.

The AW139 will act as a test case, allowing us to learn lessons which we will then apply as we roll out LCA across our product line in a progressive way.

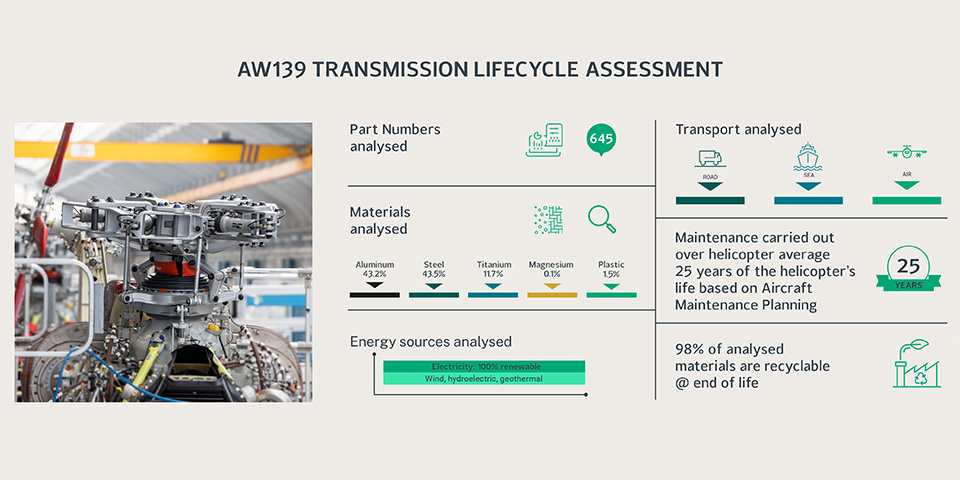

The AW139 transmission is the first major system to undergo a full LCA analysis, tracking every aspect of the transmission’s lifecycle.

How LCA works

Imagine for a moment you want to save on energy use at home. Before making any changes, first of all you need to know which devices are using the most power. Life Cycle Assessment (LCA) follows the same principle – but on a much bigger scale.

The first step is to complete an inventory analysis. This is the stage we are at right now. That means looking at every point in the product lifecycle: The raw materials we use. The volume and types of parts that go into the AW139. The manufacturing and assembly process itself. For how long the helicopter stays in flight and burns fuel. How the platform is maintained. And then there’s operational insights that operators supply to our Customer Support, Services and Training (CSS&T) colleagues via the Electronic Data Transmission capabilities of our helicopters.

Piecing all this together is like a giant jigsaw puzzle. There is a huge amount of data involved. But when the puzzle is complete, it will give us a valuable picture of the emissions hotspots within the AW139’s lifecycle. It will enable us to prioritise our improvement efforts in areas that will have the most impact.

Collaborating for success

We see LCA as a great opportunity to work together with our supply chain partners and operator community towards a common goal. We will contact the most relevant suppliers and share the approach with them. We expect that this is going to benefit both parties as LCA analysis will be required more frequently within the aviation domain in future.

We know that there is an appetite from both our commercial and Government/military customers to find ways to minimise the environmental impact of their own operations. In this way, LCA can be a ‘win-win’ for all parties involved.

What comes next?

We are still in the early stages of our LCA work. We expect to complete the full assessment of the AW139 in 2025. The next logical step will be to apply the same logic to the AWFamily of helicopters – taking advantage of the commonalities between the AW139, AW169 and AW189 types. Longer term, we envisage LCA covering our entire product line and being an integral part of how we design, develop and operate the platforms of tomorrow. It’s an exciting project and we look forward to working side-by-side with our supplier and operator community to bring it to life.

Advances in digital

The LCA project will generate huge volumes of data as we analyse the complete value chain of each product. Processing data on such a scale manually would be an impossible task. Instead, we will use our investment in areas such as Big Data and Analytics to analyse the insights and pinpoint where to target our environmental efforts.

Our work on LCA is therefore a key element of our wider digital transformation strategy. The aim is to apply the latest digital technologies to benefit our customers in areas such as product quality, process efficiency and customer satisfaction, while reducing our environmental impact.

We also foresee the opportunity to integrate LCA with our development of Digital Twins – where we create a virtual replica of our helicopters to enable rapid development and prototyping.

We see huge potential in combining the predictive insights of Digital Twins with the comprehensive environmental assessment of LCA. Together they will help us develop more sustainable rotorcraft designs for the future.

Visit the AW Vertical View homepage